MMDVII Steel Coil Tubing Price

Duplex Steel Composition

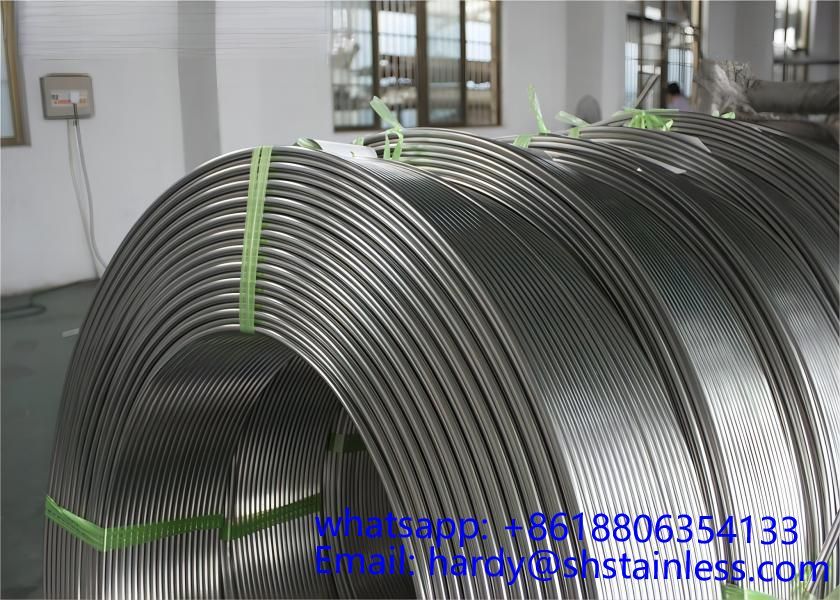

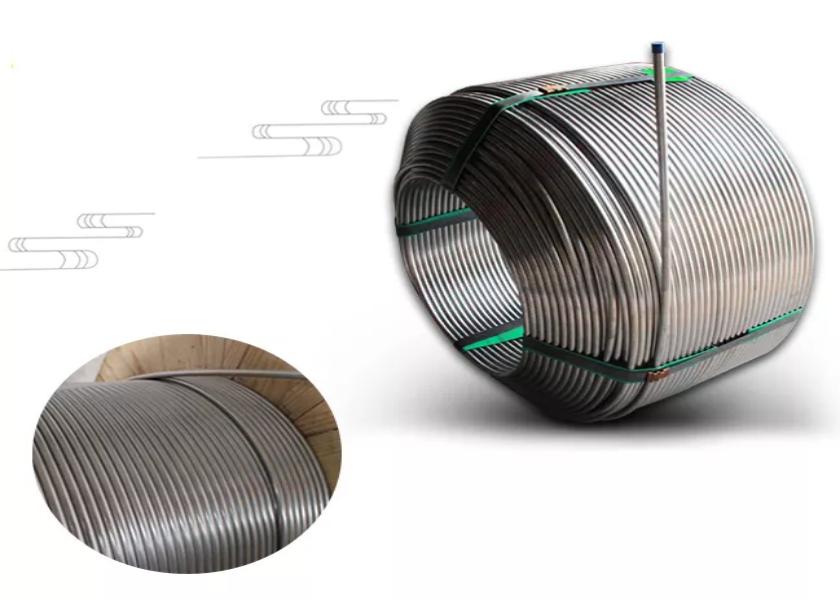

Super Duplex 2507 variis formis praesto est, ut Recta, Coiled, Seamless, Soam iuncta, frigida redrawn et annata.Applicationes typicae sunt in Subsea potestate linearum, Suboles, systemata ignis pugnandi, systemata aquarum Iniectio & saburra, caloris nummularii etc., ubi industriae praevalentes hoc Grade utentes sunt industria processus chemica et industria petrolei.

S32750 / S32760 Super Duplex Chemical Composition

| S32750 / S32760 | C | N | P | Si | Mn | Mo | Ni | Cr | S | Other |

| 0.030 | 0.24/0.32 | 0.035 | 0.80 | 1.20 | 3.0/5.0 | 6.00/8.00 | 24.0/26.0 | 0.018 | Cu:0.50 |

Super Duplex Steel S32750 / S32760 Mechanica Properties

| S32750 / S32760 | Density | Liquescens punctum | Cedant fortitudo (0.2% Offset) | Distrahentes fortitudo | Prolongatio |

| 7.8 g/cm3 | 1350 °F (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

Super Duplex 2507

Equivalent Grades S32750 / S32760 Super Duplex

| Super Duplex 2507 Standard Specification | UNS | WERKSTOFF NR. |

| Super Duplex S32750 | S32750 | 1.4410 |

| Super Duplex S32760 | S32760 | 1.4410 |

Super Duplex 2507 (UNS S32750)

Compositio %

| C Carbon | Mn Manganese | P Phosphorus | S Sulphur | Si Pii | Ni Nickel | Cr Chromium | Mo Molybdenum | N Nitrogen | Cu Copper |

| 0.003 max | 1.20 max | 0.003 max | 0.013 max | 0.80 max | 6.0–8.0 | 24.0–26.0 | 3.0-5.0 | 0.24-0.32 | 0.50 max |

Dimensiva tolerantiae

| OD | OD Tolerantia | Murus Tolerantia |

| ≤ .500" | ± .005" | ± 15% |

| 0.500"-1.500" excl | ± .005" | ± 10% |

Mechanica Properties

| Cedat imperium: | 80 ksi min |

| Distrahentes fortitudo | 116 ksi min |

| Prolongatio (min 2") | 15% |

| Duritia (Rockwell C Scale) | 32 HRC max |

Industria Applications

Processus chemica

Super Duplex 2507 destinatur ad applicationes postulandas quae vires eximiae et corrosionis requirunt resistentiae, quae in processu chemico, petrochemico et marinis instrumento inveniuntur.stannum in processibus evaporationis sal adhibendum, nummariorum caloris, et ambitus acidorum hydrochlorici.

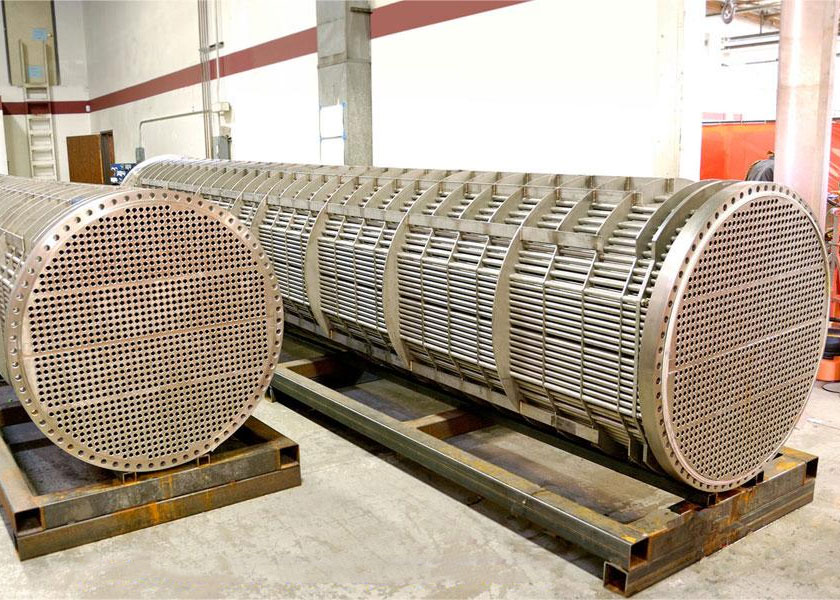

Factoy Photos

inspicienda

Shipping & Packing

Fama test