Admisce DC Aliquam Steel Coil Tubing Price

Chemical Compositio, %

Applicata corrosio typica includunt productionem dioxydum titanium (via chloride), syntheses perchlorethylenae, monomerum vinyl chloridum (VCM), et magnesium chloridum.Admisceri 600 adhibetur in fabricandis et cibis chemicis et reponendis, tractandis caloribus, phenol condensatoribus, fabrica- culo saponis, vasis acidis vegetabilibus et pingue et pluribus pluribus.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

In quibus applicationibus Inconel 600 usus est?

- Industria chemica

- Aerospace

- Caloris de industria

- Pulpam et chartam industriam

- Cibus processus

- Nuclei Engineering

- Gas Turbine components

ASTM Specifications

| Pipe Smls | Pipe iuncta | Tubus Smls | Tubus Welded | Sheet/Plate | Bar | Forging | Decens | Filum |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Mechanica Properties

Locus temperatus Typical Tensile Proprietatibus Annealed Material

| Product Form | Conditio | Tensile (ksi) | .2% Cedite (ksi) | Prolongatio (%) | Duritia (HRB) |

| Rod & Bar | Frigidus-drawn | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Hot-Finitus | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Pipe | Hot-Finitus | 75-100 | 25-50 | 35*55 | - |

| Tube & Pipe | Frigidus-drawn | 80-100 | 25-50 | 35-55 | 88 Max |

| Plate | Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Sheet | Frigidus-drawn | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel DC liquescens Point

| Elementum | Density | Liquescens punctum | Distrahentes fortitudo | Cedant fortitudo (0.2% Offset) | Prolongatio |

| Admisce 600 | 8.47 g/cm3 | 1413 °F (2580 °F) | Psi - 95,000 , MPa - 655 | Psi - 45,000 , MPa - 310 | 40% |

Inconel 600 Equivalent

| VEXILLUM | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Admisce 600 | 2.4816 | N06600 | NCF 600 | NA 13 | 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Admisce 600 Tubing

Admisceri 600 candidatus optimus est ad multos usus in summa caliditate et in ambitu multum mordax.Mixtio nickel et chromium solidam resistentiam oxidationis in temperaturis operantibus reddit.Hae temperaturae ex cryogenico usque ad ardores gradus 2,000°F vagari possunt.Summum nickel contentum offensionis 400 etiam paene-plenam resistentiam praebet ad corrosionem crepitationis accentus, quae vulgo in ambitibus chloridis invenitur.

Gravis est notare chromium portio profile chemica mixturae per gradus ad altas temperaturas sustinere posse.Structura frumenti subtilior frigido tubi perfecti, praeterea resistentia corrosionis melioris reddit, quae altiorem lassitudinem et impulsum virium complectitur.

Product Specifications

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Magnitudo dolor

| Extra Diameter (OD) | Murum crassitudine |

| 250"-.750" | .035"-.083" |

Requisita chemica

Admisce 600 (UNS N06600)

Compositio %

| Ni Nickel | Cu Copper | Fe Ferrum | Mn Manganese | C Carbon | Si Pii | S Sulphur | Cr Chromium |

| 72.0 min | 0.50 max | 6.00–10.00 | 1.00 max | 0.15 max | 0.50 max | 0.013 max | 14.0–17.0 |

Dimensiva tolerantiae

| OD | OD Tolerantia | Murus Tolerantia |

| ≤ .500" excl | +.005" | ± 12.5% |

| 500"-.750" excl | +.005" | ± 12.5% |

Mechanica Properties

| Cedat imperium: | 35 ksi min |

| Distrahentes fortitudo: | 80 ksi min |

| Prolongatio (min 2"). | 30% |

Fabricatio

Admiscere 600 processus vexillum facile conflari potest.Tractabilitas huius mixturae praeclara est, quae inter utilitatem T303 et T304.

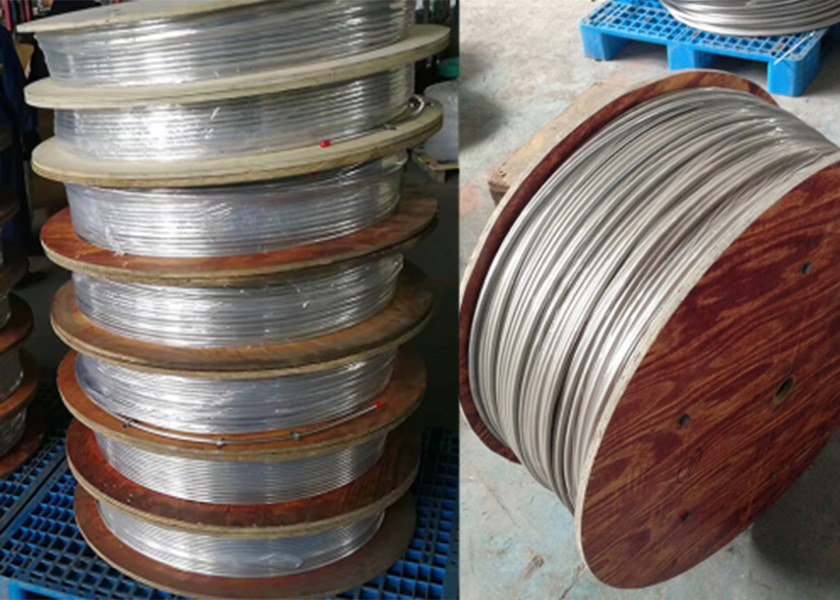

Factoy Photos

inspicienda

Shipping & Packing

Fama test