Aliquam DCXXV Steel Coil Tubing Price

Chemical Compositio, %

Mixtura 625 materia non magnetica, austenitica est, et altam distrahendi vim, fabricabilitatem et brazeability ostendit.Ob altissimum nickel contentum, hoc mixtura fere immunis est a chloride ion accentus corrosio crepuit et pitting, quod vulgo in metallis in applicationibus marinis invenitur sicut caloris nummularii, fasteners et funis vaginatus.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Reliqua | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

In quibus applicationibus Inconel 625 usus est?

- Inconel DCXXV maxime in Aerospace industriam

- Aircraft ducting systems

- Jet engine exhaurit systems

- Engine impulsus-reverso systems

- Specialioribus marinis armorum

- Processus chemica apparatu

ASTM Specifications

| Pipe Smls | Pipe iuncta | Tubus Smls | Tubus Welded | Sheet/Plate | Bar | Forging | Decens | Filum |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Mechanica Properties

| Temp° F | Tensile (psi) | .2% Cedite (psi) | Elongation in 2" (%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel DCXXV Point

| Liquescens punctum | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 Equivalent

| VEXILLUM | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | 75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

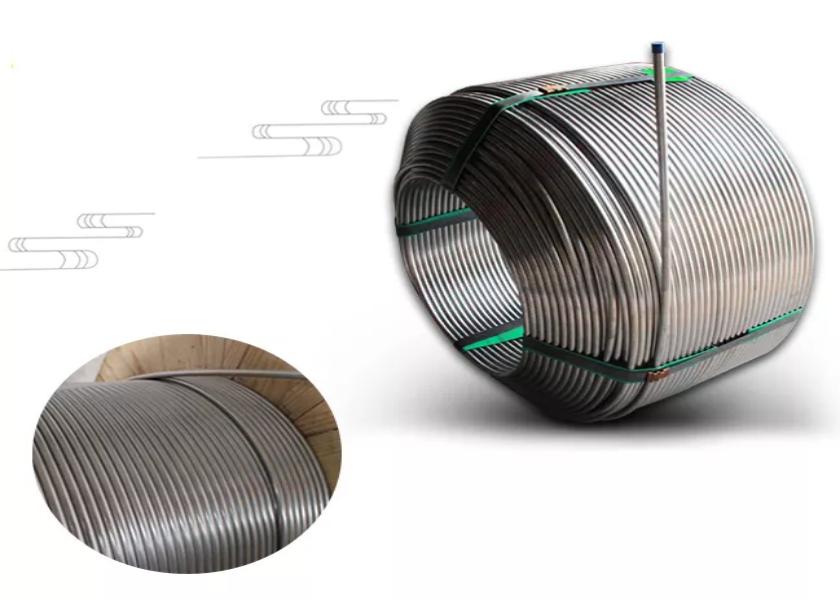

Admisce 625 Tubing

Admisceri 625 austeniticum est chromium-molybdenum superalloy notum ob rimas corrosioni et oxidationis in temperaturis elevatis resistens.Hae temperaturae ex cryogenico usque ad gradus calidissimos 1,800°F vagari possunt.Mores et compositio chemica huius gradus bene aptam faciunt applicationibus nuclei et aerospace.Item, addito niobium, mixtura 625 Tubinga invenit se auctis viribus sans caloris tractans.Haec proprietas gradum optimam optionem fingendi facit.

Product Specifications

ASTM B444 / ASME SB444 / NACE MR0175

Magnitudo dolor

| Extra Diameter (OD) | Murum crassitudine |

| .375"-.750" | .035"-.095" |

Requisita chemica

Alloy 625 (UNS N06625)

Compositio %

| C Carbon | Mn Manganese | Si Pii | P Phosphorus | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Ferrum | Al aluminium | Ti Titanium | Ni Nickel |

| 0.10 max | 0.50 max | 0.50 max | 0.013 max | 20.0–23.0 | 3.15–4.15 | 1.0 max | 8.0–10.0 | 5.0 max | 0.40 max | 0.40 max | 58.0 min |

Dimensiva tolerantiae

| OD | OD Tolerantia | Murus Tolerantia |

| .375"-0.500" excl | +.004"/-.000" | ± 10% |

| 0.500"-1.250" excl | +.005"/-.000" | ± 10% |

Mechanica Properties

| Cedat imperium: | 60 ksi min |

| Distrahentes fortitudo: | 120 ksi min |

| Prolongatio (min 2"). | 30% |

Factoy Photos

inspicienda

Shipping & Packing

Fama test